CODA – Development of an environmentally friendly process for the production of soda ash

In the CODA (Carbon-negative sODA ash plant) project, a new sustainable and carbon-negative process is being developed for the pilot scale production of calcined soda ash (sodium carbonate) from rock salt brine, renewable energy, and atmospheric CO2.

The CODA project is intended to establish the foundation for replacing the conventional ammonia-soda process, and producing soda ash in a more ecologic, economic and social sustainable manner.

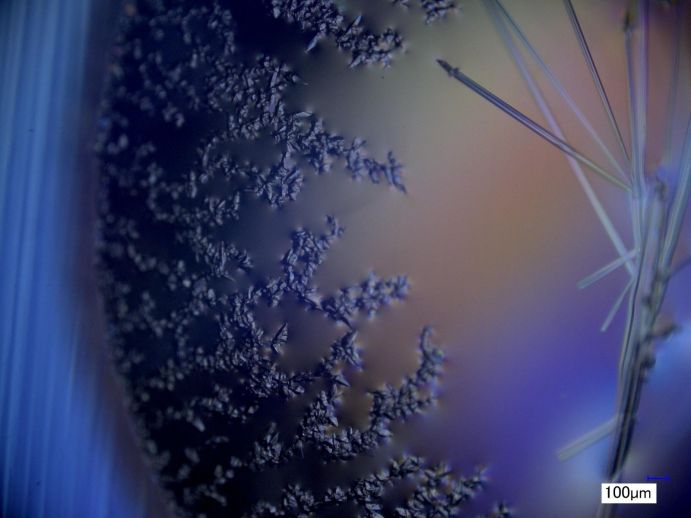

The CODA project is aimed to develop a new environmentally friendly process for the production of soda ash using atmospheric CO2 by direct air capture (DAC) and caustic soda generated by electrolysis of rock salt brine using renewable electrical energy. Hydrogen and chlorine are also produced as valuable by-products of the electrolysis.

The CODA process not only avoids carbon dioxide emissions (Carbon Direct Avoidance, CDA), but also removes carbon dioxide from the air (Carbon Capture and Utilization, CCU). In comparison to the ammonia-soda process, emissions totaling around 900 kg of CO2 per ton of soda ash produced can be avoided (around 500 kg by CDA) and absorbed (around 400 kg by CCU).

A particular challenge in the development of the CODA process is the strong dependence of the process on the weather conditions. The generation of renewable electricity from the sun and wind is just as dependent on the weather conditions as the CO2 direct air capture from atmospheric humidity and temperature. Therefore, the process must be adaptable to the climatic conditions and seasons through a large operation window.

In the course of this project, at first the physical and chemical process fundamentals are developed, experimental work is carried out on a process laboratory scale and process models are created at the Max Planck Institute DCTS in Magdeburg. Subsequently, a CODA pilot plant (TLR5) will be built in the soda plant of CIECH Soda Deutschland (CSD) in Staßfurt and tested under practical conditions. An accompanying sustainability assessment based on determined experimental and model data will evaluate the new process in comparison to the state of the art and will help to make process design decisions. If the trial operation of the pilot plant is successful and the sustainability assessment positive, the project results can be used by CSD to plan an industrial production facility.

Project management

apl. Prof. Dr. Heike Lorenz

Max Planck Institute for Dynamics of Complex Technical Systems

Phone: +49 391 6110 293

E-Mail: lorenz@mpi-magdeburg.mpg.de

Last updated on